Fotona Technology

Lasers are the Heart of our Business

Exceptional R&D Expertise

At Fotona we pride ourselves on our technical know-how and experience in research and development. Our comprehensive range of class-leading laser systems for various industries is testimony to our technological expertise. Fotona’s advanced research and development capabilities and infrastructure enable us to push the limits of laser technology and set new standards of excellence in the industry. We have established a tradition of rising to the challenges of rapidly evolving technology, which demands adopting a multidisciplinary approach to meeting the long-term needs of our customers.

Patented, Leading-edge Medical Technology

Fotona’s unique R&D expertise and patented technological solutions have enabled us to design and manufacture the world’s most advanced medical laser systems powered by Er:YAG, Nd:YAG and Q-Switched laser technologies. At the heart of Fotona’s medical lasers are high-performance, solid-state crystal laser sources that generate the industry's most proven and effective treatment wavelengths. These “golden-standard” wavelengths are ideally suited for handling an exceptionally wide range of aesthetic and clinical procedures. Fotona's proprietary handpieces, innovative operating modes and advanced beam-profile technologies further enhance these golden-standard medical wavelengths to ensure maximum performance and efficacy.

Visit the main sections of our website to learn more about how Fotona's advanced laser technologies are enabling faster, less invasive, and more effective treatments in areas such as Aesthetics & Dermatology, Dentistry, Surgery and Gynecology.

Superior Pulse Technology

An example of Fotona’s technological expertise can be seen in our patented VSP (Variable Square Pulse) technology, which creates precisely controlled sequences of square-shaped pulses that serve to maximize patient safety by minimizing excess laser energy absorption into the skin and other body tissues. VSP pulses avoid the slow rise and even longer drop-off in pulse power that is common in less-advanced light-based technology platforms. Slow rises and long falls in pulse power transfer unnecessary laser energy to body tissues, which is then inefficiently converted to heat, increasing the risk of unwanted side effects and reducing the efficacy of the treatment. Fotona’s VSP technology eliminates the problem of heating surrounding tissues, enabling practitioners to confidently and precisely treat specific body tissues with unmatched efficacy.

Energy Feedback Control

Another of Fotona’s pioneering safety features, EFC (Energy Feedback Control) actively monitors and controls each individual laser pulse’s energy level using a sophisticated double-channel safety structure to provide the highest possible degree of safety for all procedures. EFC avoids uncontrolled losses of energy that are inherent in less-advanced laser technology platforms, and ensures efficient and effective operation each time the system is used.

With EFC, the laser output energy is continuously regulated by two energy meters, ensuring that the output energy is exactly matched to the chosen treatment parameters for safe and effective operation. In addition, an added benefit of EFC technology is that Fotona laser systems do not require a tedious and inconvenient manual calibration procedure each time the system is switched on.

OPTOflex® and Vacuum Cell Technologies

Fotona’s advanced Q-switched lasers are equipped with groundbreaking optical solutions such as patented OPTOflex® and Vacuum Cell technologies to produce an almost perfectly homogeneous beam profile. This ensures greater safety during treatments since the laser energy is evenly distributed across the treated area. Epidermal damage is minimized and the risk of bleeding, tissue splatter and transient textural changes in the skin is decreased.

These and other core Fotona technologies give healthcare practitioners the peace of mind that the laser parameters they have selected are being safely and precisely delivered by the system throughout the entire treatment, thereby providing a level of safety and confidence in their system’s ability that cannot be matched by any other laser manufacturer.

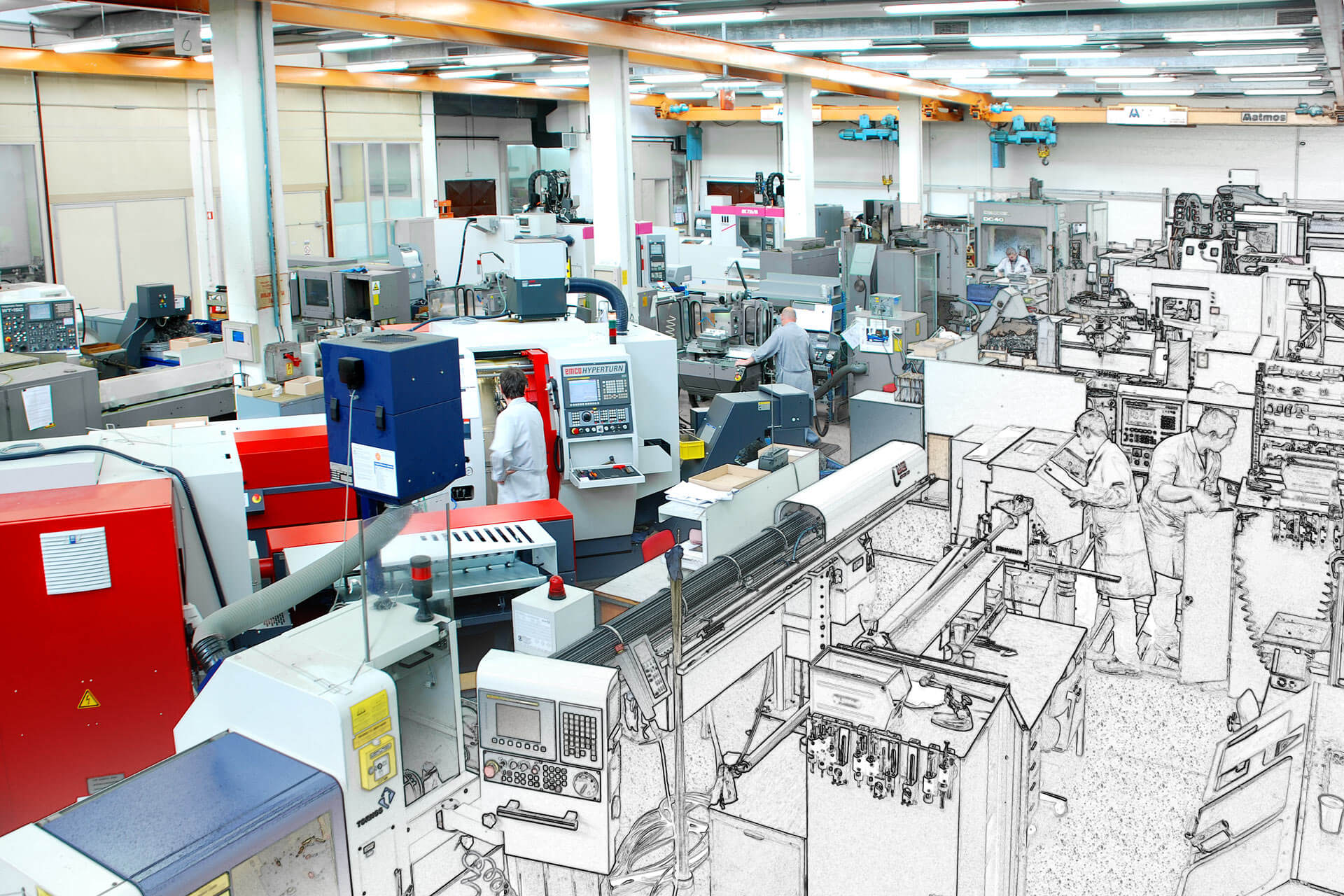

In-house Design & Production

Fotona's ability to design and manufacture the most demanding system components in-house has proven to be a major competitive advantage in the laser industry. The majority of the electronics hardware and software assemblies for our laser systems are developed internally, with stringent manufacturing and control processes in place to ensure the highest attainable levels of precision, reliability and safety for all of our systems.

Our modern, CAD/CAM production of optomechanical components ensures high precision for even the most complex subassemblies, regardless of the source material (aluminum alloys, casts, stainless steel, titanium, brass, bronze or synthetics).

At Fotona our business philosophy is simple: we aim to choose perfection in all of our products. When you choose Fotona, you choose a company committed to designing, manufacturing and delivering the highest performance, best made laser systems in the world.